Location: Penticton, BC, Okanagan Valley, Canada

Zone: Hardiness Zone 6

Name: Olaf

Join Date: Apr 2010

Posts: 1,705

Said "Thanks" 2,050 Times

Was

Thanked 2,012 Times in 876 Posts

|

Re: Permanent banana shelter for winter and spring

Re: Permanent banana shelter for winter and spring

List of tools:

1. Cutting schematic for two single pseudo stem shelters and one pad shelter (works out well on three sheets of Styrofoam)

2. Three 4 x 8’ sheets of 1” Styrofoam

3. One cutting knife with complete blade

4. One roll of masking tape

5. One bullet point felt marker

6. One roll of prime grade Duct Tape (not the inferior Duck Tape or such)

7. One 4 feet long cutting guide, preferably a carpenter’s level

8. One large right angle guide

9. One tape measure

10. One large card board cutting base ( may be a cut open and flattened box)

11. Weldbond glue, at least 12 Fl oz. (~340 ml)

Optional:

• .Paint

• A coupling for white PVC irrigation pipe, 1½ or 2 inches diameter.

Cutting the parts:

A good base of corrugated cardboard will last you through the whole job. Mark the Styrofoam

sheets as shown in the schematic:

. .

When cutting it is important to hold the cutting knife vertical and flat in the direction of the cut, to

ensure it to be clean and smooth. If the cuts are not reasonably vertical you will not get good

contacts when you assemble the parts later. A carpenter’s level is thick and will thus also provide you

with some vertical guidance for the cut, which a simple flat straight edge will not. The parts on the

schematic are labelled OP for outer panel and IP for inner panel. KFL stands for "keep for lid".

Assembling the shelters:

When you stick two panels together, place one flat on the floor, attach masking tape strips

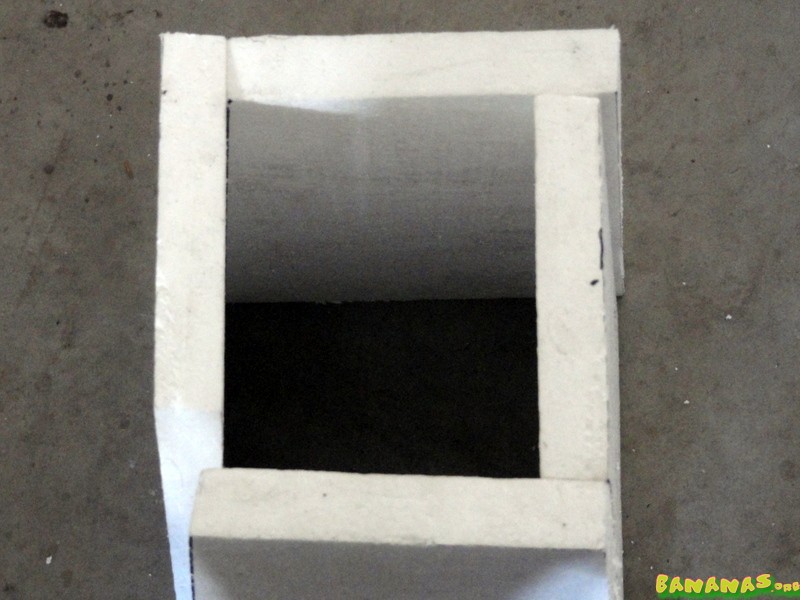

underneath and then apply a generous bead of glue along the edge. As shown in this picture:

It helps to get the proper right angle, because SF is rather rigid stuff and not easy to correct later

I did that by brazing the panels in the inside with a rectangular ruler and then span masking tape

across to hold it in place as shown here:

While that glue is setting, you may want to stick the other two panels together. With the

second two panel set it is important, that you make sure, that the flat panel to edge sequence

can follow continuously in the same direction, not as shown in this photo:

The panel at the bottom of this photo should have butted with its edge to the flat of the right

panel. I was lucky to make that error with the first shelter, thus I was able to stick those for

second one together in a manner to achieve the proper sequence for both

Once you have both, the inside and the outside shell assembled and the glue has properly set, you

will want to glue in the 3” spacers. You do not want to make them too high, so they won’t get in the

way when stuffing in the glass fibre insulation later. I made mine a bit less that 3” high (7 cm). Use

the smallest leftovers, which will suffice, since you will need the larger ones for the lid.

This photo only shows the top spacers, you want to stick others in the bottom the same way.

I.e., you want 8 ea. 3” x 2½ ” spacers for each shelter

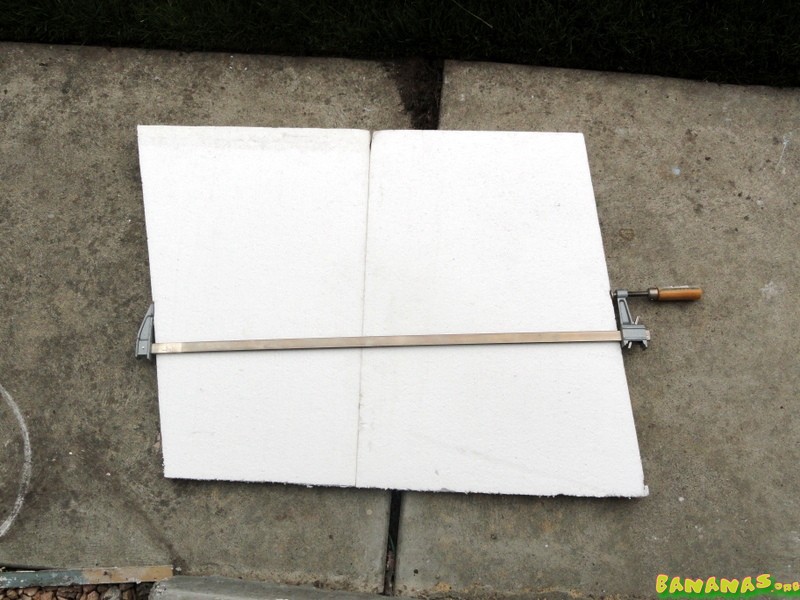

If you make the same number of shelters from 3 sheets as I did, you will have to glue some of

the larger pieces together for the lid as shown here:

Gluing the foam edge to edge is not a problem, because it will break before the glue will come apart.

I have cut the lid two inches larger than the outside of the top of the shelter walls to achieve a

1 inch overhang. Cut a square for each of the shelters to fit into the inner walls, 5“ square for the

single stem ones and 12 inches square for the whole pad shelter and glue them to the centre of the

lids, as shown here:

Grooving the bottom of the lid with a triangular file about ¼ inch from the edge as you may be able

to see here, will prevent any water from traveling along the bottom into the shelter.

The photo below shows the use of Duct Tape to reinforce the joints and top and bottom edges,

as well as the positioning of the shelter “in the field”, held in place by 4 bamboo poles and

weighed down with a rock, so it cannot blow away, That allows for easy repeated removal and

replacement in spring according to weather conditions:

Optionals

Here is the whole group all decked out in a brand new paint job, which is actually not required,

as Styrofoam is as weather resistant as any paint, but the latter looks better.

The other optional is actually just a tip. I am using couplings for PVC irrigation pipe to keep

the glue flowing toward the ‘exit’. To stick the bottle upside down into one after each use saves a

lot of time and aggravation  Ah yes, because I do not always (want to) close the top, it Ah yes, because I do not always (want to) close the top, it

sometimes drips. Over the years the paper toweling I placed below as drip catcher has formed with

the glue a solid bottom.

I use the same method with a few couplings in the fridge for ketchup and salad dressing etc.

__________________

The reason I joined this forum was to share experiences,

my own and those of others and to learn from them.

|